Production of metal/metal oxide nanoparticles

Production of metal/metal oxide nanoparticles

Metals such as silver, gold, copper, etc. have approved their effectiveness in various treatments as well as the synthesis of various drugs. In recent years, the usage of metal nanoparticles has been widely welcomed in research, development, and therapeutic work. In Histogenotech Company, various types of metal nanoparticles such as gold nanoparticles (Au), copper oxide (CuO), iron oxide (FeO), silver (Ag) and so on, are produced.

Silver nanoparticles have antibacterial, antifungal and anti-inflammatory properties. Besides they are environmentally friendly, non-irritating, non-allergenic, heat resistance and have high stability, which attracted the attention of researchers. The antibacterial properties of these nanoparticles have led to their widespread use in wound dressings and all devices involved in the wound healing process. Silver nitrate is used as the basic material to produce silver nanoparticles. In addition, a variety of reductants such as sodium citrate, sodium borohydride, hydrazine, hydroquinone, sodium ascorbate etc. can be used.

Mn++ nBH4– —–> M0 + nB(OH)3 + n3.5H2

AgNO3 +NaBH4 —–> Ag + H2 + B2H6 + NaNO3

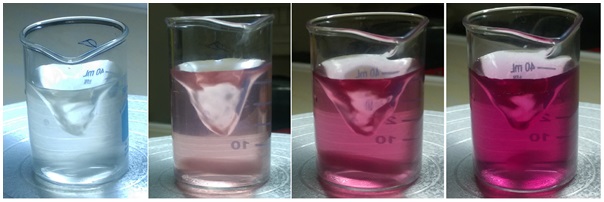

After reduction, it is necessary to stabilize the formed nanoparticles, so the stabilizers can be employed. Stabilizers include polyvinyl pyrrolidone, sodium hydroxide, polyethylene glycol, trisodium citrate, and sodium citrate. After forming the nanoparticles, the color of the solution changes. This color can vary depending on the stabilizer and reductant. In Spite of this, the color of silver nanoparticles tends to be gray. In order to separate the nanoparticles, the final colloid is centrifuged and finally the nanoparticles are washed several times with distilled water.

Hydrogel nanoparticles

Hydrogel nanoparticles are three-dimensional polymeric networks that are used to encapsulate and transfer drugs, growth factors, and molecules. These structures swell in water or bio-environment and carry large amounts of these fluids. There are also responsive hydrogels that are stimulated by the environment, such as changes in temperature and pH, to release the drug. These systems are also employed for transmitting DNA and proteins, wound healing, biosensors and tissue engineering. Depending on the type of the used polymer, there are different protocols to produce hydrogel nanoparticles. Chitosan nanoparticles are the most produced hydrogel nanoparticle in Histogenotech Company. In order to prepare the chitosan solution, different concentrations (e.g. 1% w / v) of chitosan can be prepared. a 1-3% solution of acetic acid can solve chitosan. Cross-linkers cause linking and hydrogel formation. These include Glutaraldehyde, Genipin, polyvinyl pyrrolidone (PVP), calcium chloride, UV, and temperature. Depending on the polymer, the cross-linker can be different. In order to produce hydrogel nanoparticles, a dilute solution of cross-linker is added dropwise to the chitosan solution. Due to the formation of hydrogel nanoparticles, the color of the solution turns to milky

Related Content: drug-carrier nanoparticles – Production of nanoparticles carrying plant extracts