Production of nanoparticles carrying plant extracts

Production of nanoparticles carrying plant extracts

The purpose of extracting is to obtain medicinal substances (active ingredients) in plants (roots, leaves, flowers, etc.) or other mineral and animal resources. These active ingredients are used in the pharmaceutical industry, especially in herbal medicine and traditional medicine, and in many cases can be a good alternative to commercial drugs.

Histogenotech , by developing the plant extraction unit (extract, essential oil and volatile oil), not only can produce various extracts, but also by relying on its internal knowledge and expert Manpowers, has the potential to encapsulate and produce nanoparticles carrying various herbal extracts.

Synthesis of ginger plant nanoparticles

Gingerol is the main bioactive compound in ginger, which not only has a potent anti-inflammatory and antioxidant effects, but is also known as a strong anticoagulants which lowers blood cholesterol.

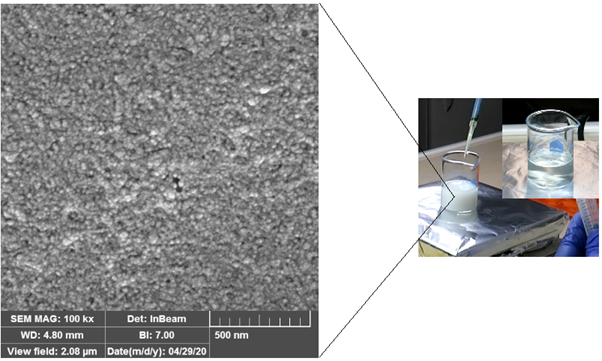

Since, one of the properties of nanoparticles is to enhance the drug delivery efficiency, the production of nanoparticles carrying ginger extract can enhance the effectiveness of this herbal medicine. With the production of nanoparticles carrying this extract, Histogenotech Company has been able to conduct various research such as treatment of MS, heart attack, and cancer in animal models. In the R&D unit of Histogenotech Company, the synthesis of nanoparticles is carried out by encapsulation of active ingredients using various biopolymers. In order to preserve and stabilize these nanoparticles and their polymeric shell, various cross-linkers such as sodium tripolyphosphate (TPP) are used. The nanoparticles are finally separated using centrifugation. In order to remove excess biopolymers and additional chemicals, the resulting nanoparticles are washed several times using deionized water. Then add a certain amount of deionized water to the nanoparticles and start sonication. The final colloids are stored in 5, 10, 15 and 20 ml vials. It should be noted that the final colloidal concentration can vary according to the study protocol and details of the project.

Production of nanoparticles carrying plant essential oils

Essential oils, like plant extracts, have significant healing properties and have always been of interest to researchers. The main difference between essential oils and plant extracts is that the plant extracts are hydro-alcoholic, while the essential oils are oily and require initial preparation to produce nanoparticles. Vegetable oils with healing properties such as olives also fall into this category.

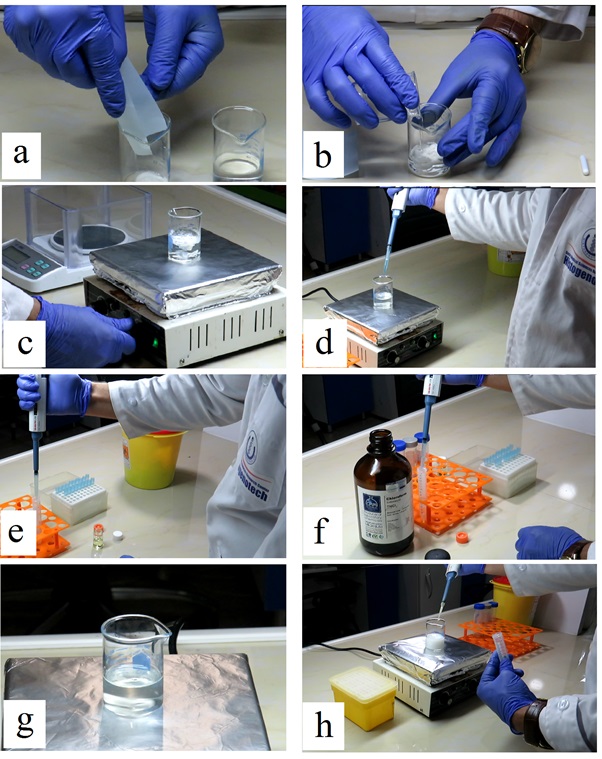

The protocol for the production of nanoparticles containing extracts differs in some stages from the corresponding protocol with essential oils. After preparing the polymer solution, we dissolve the essential oil, which has an oily phase in the chloroform, to obtain an organic phase with a very low viscosity. Then we add the organic phase drop by drop to the polymer solution under stirring. At this stage, the color of the mixture changes to milky. Finally, we add the cross-linker (network agent) drop by drop. Then, the nanoparticles are separated by centrifuge. In order to remove biopolymers and additional chemicals, they are rinsed several times using deionized water. Then add a certain amount of deionized water to the pellets and sonicate the mixture to reach a uniform colloid. The final colloids are stored in 5, 10, 15 and 20 ml vials. It should be noted that the final concentration can vary according to the project.

Related Content: drug-carrier nanoparticles – Extraction of essential oil and active ingredient of Medicinal plants